Cookie preferences

This website uses cookies, which are necessary for the technical operation of the website and are always set. Other cookies, which increase the comfort when using this website, are used for direct advertising or to facilitate interaction with other websites and social networks, are only set with your consent.

Configuration

Technically required

These cookies are necessary for the basic functions of the shop.

"Allow all cookies" cookie

"Decline all cookies" cookie

CSRF token

Cookie preferences

Currency change

Customer recognition

Customer-specific caching

Individual prices

PayPal payments

Selected shop

Session

Comfort functions

These cookies are used to make the shopping experience even more appealing, for example for the recognition of the visitor.

Note

Store Locator

Statistics & Tracking

Affiliate program

Track device being used

€619.95 *

Prices incl. VAT plus shipping costs

Ready to ship today,

Delivery time appr. 2-4 workdays

Do you have any questions about the product or availability?

- Order number: 2670

This newly developed ballast renewal machine from Plasser & Theurer is equipped with two drive... more

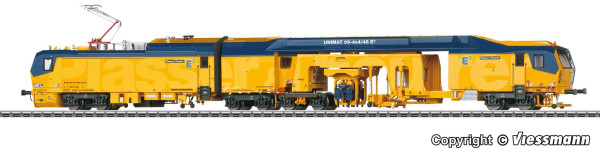

Product information "H0 Unimat 09-4x4/4S E³ Tamping machine, P & T, functional model for 2 rail version"

This newly developed ballast renewal machine from Plasser & Theurer is equipped with two drive options – electric and diesel-electric (hybrid) – by

means of a 600 kW diesel engine. Driving engines and hydraulics are always driven electrically. The electric drive allows for a low-maintenance, as well

as silent and low-emission operation (CO2-reduced).

The trendsetting design is mainly function-orientated and keyed to enhance work safety. The model is to a high degree a copy of the prototype in terms

of both function and design.

Innovation by Viessmann:

Operation optional in drive mode or working mode travelling forward at ca. 1 km/h with tamping unit moving vertically and horizontally. Pantograph motor-

driven, several light functions. Digital decoder with original sound for electric resp. diesel engine for DCC, MM and analogue mode DC, compatible

with RailCom. Excellently synchronized tamping unit with the drive motors and the sound. Premium two-part model with zinc diecasting chassis and two

synchronized drive motors ensuring a dynamic yet sensitive train operation, supported by integral current memories.

With coupler pockets acc. NEM 362 and attached system coupling.

Dimensions: Lob 39,3 x W 3,9 x H (without/with pantograph) 5,1/7,6 cm.

Weight: 650 g

Functions in analogue mode:

- Driving mode forward / reverse

- Switchable functions: Working mode with fully functional tamping unit, synchronized with the drive motors and the sound, incl. warning light and working lights

- Sound active

- Light active (configurable by CVs)

Functions in digital mode:

- Driving mode forward/reverse

- Switchable functions: Working mode with fully functional tamping unit, synchronized with the drive motors and the sound (slide movement forward and backward, tamping movement, also all individually switchable)

- Sound, horn

- Pantograph up/down

- Shunting mode

Switchable light functions in digital mode:

- Coach lighting white or blue

- Headlights switchable individually acc. to direction of travel as well white/red, high and low beam switchable

- Stoplight

- High beam

- Operator’s cab lighting

- Work space lighting

- Warning light front and back

means of a 600 kW diesel engine. Driving engines and hydraulics are always driven electrically. The electric drive allows for a low-maintenance, as well

as silent and low-emission operation (CO2-reduced).

The trendsetting design is mainly function-orientated and keyed to enhance work safety. The model is to a high degree a copy of the prototype in terms

of both function and design.

Innovation by Viessmann:

Operation optional in drive mode or working mode travelling forward at ca. 1 km/h with tamping unit moving vertically and horizontally. Pantograph motor-

driven, several light functions. Digital decoder with original sound for electric resp. diesel engine for DCC, MM and analogue mode DC, compatible

with RailCom. Excellently synchronized tamping unit with the drive motors and the sound. Premium two-part model with zinc diecasting chassis and two

synchronized drive motors ensuring a dynamic yet sensitive train operation, supported by integral current memories.

With coupler pockets acc. NEM 362 and attached system coupling.

Dimensions: Lob 39,3 x W 3,9 x H (without/with pantograph) 5,1/7,6 cm.

Weight: 650 g

Functions in analogue mode:

- Driving mode forward / reverse

- Switchable functions: Working mode with fully functional tamping unit, synchronized with the drive motors and the sound, incl. warning light and working lights

- Sound active

- Light active (configurable by CVs)

Functions in digital mode:

- Driving mode forward/reverse

- Switchable functions: Working mode with fully functional tamping unit, synchronized with the drive motors and the sound (slide movement forward and backward, tamping movement, also all individually switchable)

- Sound, horn

- Pantograph up/down

- Shunting mode

Switchable light functions in digital mode:

- Coach lighting white or blue

- Headlights switchable individually acc. to direction of travel as well white/red, high and low beam switchable

- Stoplight

- High beam

- Operator’s cab lighting

- Work space lighting

- Warning light front and back

Available downloads:

BUNDLE

Content 25 meter (€0.32 * / 1 meter)

€7.95 *

BUNDLE

Viewed